How Next-Generation Manufacturing Redefines Form and Function

In an age where technology seamlessly integrates into daily life, a quiet revolution is unfolding in the realm of material science and fabrication techniques. Flexible electronics, once confined to the realm of research labs, are now on the cusp of mainstream adoption, driven by groundbreaking advancements in manufacturing processes and material innovation.

The Convergence of Materials and Processes

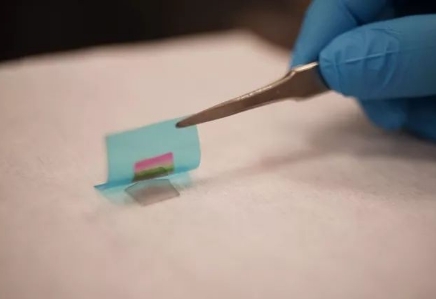

The key to flexible electronics lies in the ability to combine high-performance materials with manufacturing methods that accommodate bendability and stretchability. Graphene, a single-atom-thick carbon layer, has emerged as a star player due to its exceptional electrical conductivity (200,000 cm²/V·s) and mechanical strength (130 GPa). Researchers have developed roll-to-roll printing techniques to deposit graphene-based inks onto flexible substrates like polyimide, enabling the mass production of transparent conductive films with sheet resistances as low as 10 Ω/sq.

Another breakthrough material is perovskite, renowned for its high light-harvesting efficiency in solar cells. Scientists have successfully transferred perovskite thin films onto flexible PET substrates using a blade-coating method. These flexible perovskite solar modules achieve a power conversion efficiency of 22.3%, comparable to rigid counterparts, while withstanding 1,000 bending cycles at a radius of 5 mm without significant performance degradation.

Manufacturing Innovations Pushing Boundaries

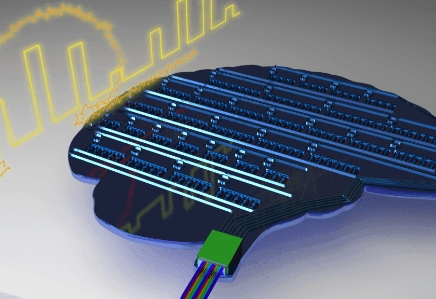

Additive manufacturing, or 3D printing, has found new applications in flexible electronics. Aerosol jet printing technology allows for the precise deposition of functional inks, including silver nanoparticles for conductors and PEDOT:PSS for organic semiconductors. This technique enables the creation of complex 3D circuit geometries, such as spiral antennas that conform to curved surfaces. In a recent study, researchers printed fully functional RFID tags on fabric using this method, achieving read ranges of up to 2 meters.

For high-volume production, microcontact printing (μCP) offers nanoscale precision. By using elastomeric stamps to transfer materials onto flexible substrates, μCP can replicate intricate patterns with feature sizes down to 50 nm. This technology is pivotal in fabricating flexible OLED displays, where it enables the precise alignment of organic layers, resulting in pixel densities exceeding 1,000 PPI.

Transforming Industries with Flexible Electronics

In the healthcare sector, flexible electronics are revolutionizing patient monitoring. Stretchable epidermal sensors, made from a composite of PDMS and nanowire transistors, can continuously measure physiological signals like heart rate, skin temperature, and muscle activity. These sensors adhere to the skin via van der Waals forces, providing accurate data for up to 72 hours without causing discomfort. In a clinical trial, such sensors detected early signs of sepsis with 95% accuracy, significantly improving patient outcomes.

The automotive industry is also embracing flexible technology. Flexible thin-film heaters integrated into car seats can distribute heat more evenly, consuming 30% less power than traditional resistive heaters. Additionally, flexible Li-ion batteries with a bend radius of 10 mm are being developed for electric vehicles. These batteries can be shaped to fit unconventional spaces, increasing vehicle design flexibility while maintaining energy densities of 250 Wh/kg.

As flexible electronics move from niche applications to widespread use, the interplay between material science and manufacturing innovation will continue to drive progress. These adaptable, form-fitting technologies are not just redefining how devices look and feel but also expanding the possibilities of what electronics can achieve in diverse fields, from wearable health monitors to next-generation automotive systems.