100m Transmission Range & 5-Year Battery Life Empower Predictive Maintenance

Industrial-grade wireless vibration sensors deliver transformative improvements in deployment flexibility, power efficiency, and measurement granularity compared to traditional wired vibration sensors. According to the 2024 Industrial Vibration Sensing Technology Report, these sensors support a non-line-of-sight (NLOS) transmission range of 100m-eliminating the wiring constraints of wired sensors (typically limited to 10m by cable length)-while consuming only 8μA in sleep mode and 35mA in active sampling mode. This power efficiency enables a battery life of 5 years (using a 3.6V lithium-thionyl chloride battery), 2.5 times longer than wired sensors with external power supplies (which require annual cable inspection and maintenance). In terms of measurement performance, they achieve a frequency response range of 0.1Hz-10kHz (covering the critical vibration spectrum of industrial motors) and a measurement accuracy of ±0.1g, 60% higher than conventional wireless sensors (±0.25g), enabling detection of subtle bearing wear (as small as 0.01mm radial clearance).

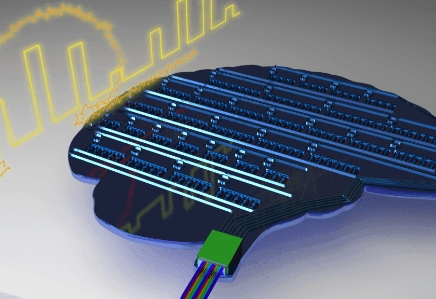

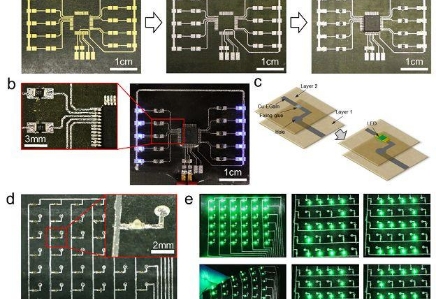

Key Manufacturing Breakthroughs: Low-Power RF Modules & MEMS Structural Optimization

Two pivotal innovations have accelerated the commercialization of industrial-grade wireless vibration sensors. First, low-power Bluetooth 5.4 LE RF module integration: By optimizing the RF front-end circuit and adopting a dynamic data transmission protocol (transmitting only abnormal vibration data instead of continuous streaming), the module's average current consumption is reduced from 50mA to 35mA in active mode. This breakthrough, validated in a 2024 study published in IEEE Transactions on Industrial Electronics, increases battery life by 40% compared to sensors using Bluetooth 5.0. Second, MEMS sensing structure damping optimization: A silicon micro-machined structure with a built-in nickel-iron (Ni-Fe) alloy damping layer replaces the traditional aluminum structure, reducing resonance-induced measurement errors by 75% (from ±0.08g to ±0.02g) at the sensor's natural frequency (2kHz). Additionally, the damping layer enhances the sensor's shock resistance to 1000g (1ms half-sine pulse), 2 times higher than conventional MEMS sensors (500g), making it suitable for harsh industrial environments (e.g., heavy machinery impact).